dachy płaskie

Systemy dachowe

Wszystko, co musisz wiedzieć o dachach

Odkryj tajniki tworzenia trwałego dachu, instalacji okien, montażu rynien oraz wykonywania obróbek blacharskich. Poznaj zarówno klasyczną, jak i nowoczesną architekturę dostępną dla każdego, z wykorzystaniem wysokiej jakości materiałów i najnowszych technologii.

Okna do dachów płaskich – na co zwrócić uwagę?

Naturalne światło słoneczne jest cenione za liczne korzyści, w tym za dostarczanie witaminy D, która wspiera wzrost kości, reguluje układ odpornościowy i może nawet poprawić jakość snu. Jakie to ma związanie z oknami dachowymi do dachów płaskich? W naszym przewodniku...

Okna do dachów płaskich – na co zwrócić uwagę?

Naturalne światło słoneczne jest cenione za liczne korzyści, w tym za dostarczanie witaminy D, która wspiera wzrost kości, reguluje układ odpornościowy i może nawet poprawić jakość snu. Jakie to ma związanie z oknami dachowymi do dachów płaskich? W naszym przewodniku...

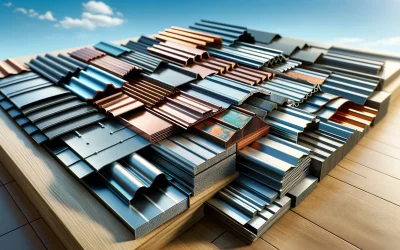

Jakie są różne rodzaje metalowych materiałów dachowych?

Gdy mówimy o "metalowym dachu", zazwyczaj myślimy o dachu stalowym. Jednak istnieje więcej rodzajów metalowych pokryć dachowych niż tylko stalowe panele. Choć są one mniej popularne, oferują wszystkie zalety wynikające z wykorzystania metalu jako materiału na dach....

Materiały na dach płaski – trendy

Dachy płaskie są często spotykane w różnych rodzajach budynków, lecz wybór takiego dachu dla danej konstrukcji wymaga przemyślenia. Ich charakterystyka różni się od estetycznie atrakcyjnych dachów spadzistych, powszechnie stosowanych w budownictwie jednorodzinnym i...

Poliwęglan nie tylko jako materiał na elementy dachowe

Spis treści:WstępProfile z poliwęglanuOsłony z poliwęglanuArmatura z poliwęglanuObudowy poliwęglanoweSystemy wentylacyjneZbiorniki z poliwęglanuZakończenie Wstęp Poliwęglan, często kojarzony głównie z zastosowaniami w budownictwie jako materiał na elementy dachowe, w...

Spieki kwarcowe – wiedza podstawowa

W kontekście wyboru twardych powierzchni dla projektów budowlanych lub architektonicznych, dostępna jest szeroka gama materiałów. Wśród nich znajdują się naturalne opcje, takie jak kamień czy drewno, a także te stworzone przez człowieka. Spiekany kamień to jeden z...

ZASTOSOWANIE PŁYT WARSTWOWYCH I WYMAGANIA MONTAŻOWE

Chociaż płyty warstwowe są jednym z najnowszych materiałów w nowoczesnym budownictwie, ich rozwój nie stoi w miejscu. Budownictwo i technologia produkcji płyt warstwowych nieustannie się ulepszają, co pozwala na nadawanie tej konstrukcji nowych, zaawansowanych...

ŚWIETLIKI: WYBÓR, ZAKUP I INSTALACJA ( 2024 )

Świetlik dachowy to rodzaj okna dachowego, specjalnie zaprojektowanego do maksymalizacji wykorzystania naturalnego światła słonecznego, dostarczając w ten sposób źródło naturalnego oświetlenia. Znane są pod różnymi nazwami, takimi jak światła dachowe, okna połaciowe,...

Zarządzanie niechcianymi zapachami – filtry antyodorowe

Zarządzanie niechcianymi zapachami stanowi wyzwanie w wielu branżach przemysłowych. Podczas gdy usuwanie pyłu i innych cząstek stałych z powietrza jest zazwyczaj procesem prostym, identyfikacja i eliminacja zapachów często wymaga zastosowania bardziej zaawansowanych...

Projekt komina i kanału spalinowego

Konstrukcja i zastosowanie kominów oraz kanałów spalinowych podlegają przepisom budowlanym, włączając w to odpowiednie standardy europejskie i polskie. Chociaż te przepisy różnią się w pewnych aspektach, wszystkie nakazują bezpieczny montaż komina, niezależnie od...

Wszystko, co musisz wiedzieć o systemach odwadniających wody deszczowej

Podczas gdy deszcz może przynosić korzyści dla roślin na podwórku lub w ogrodzie, może stworzyć poważne kłopoty w innych częściach nieruchomości, zwłaszcza jeśli nie masz właściwego systemu odprowadzania wody deszczowej. Stojąca woda może negatywnie wpływać na stan...